In a world where the loom and shuttle once stood as symbols of technological ingenuity, the textile industry finds itself at the precipice of another transformative era. Long considered a bastion of manual labor, this age-old sector is now entwining its fibers with the cold precision of robotics.

As we stand on the cusp of this metamorphosis, questions abound: How is the delicate dance of thread and needle being reimagined through the lens of automation? Can the age-old artistry of textile creation coexist with the unerring accuracy of machines?

Understanding the future of textile manufacturing isn't just about getting to grips with robotic arms and the complex algorithms that run them. It's much more than that. We will explore how textiles and technology have always been closely linked and how they're weaving together a new chapter in manufacturing. It's a fascinating story that goes beyond gears and codes, tapping into the heart of human innovation and progress.

In ancient civilizations, textiles were more than just fabrics; they were stories, histories, and identities woven into tangible forms. The hands that crafted them were revered, and their skills were passed down through generations.

Now, as robotic arms replace human hands, we find ourselves at a crossroads. Does the essence of a craft lie in the act of creation or in the end product? And as we edge closer to a future where machines dominate, what becomes of the human touch?

Looking back, the Industrial Revolution reshaped societies, economies, and cultures. Machines, once seen as threats, eventually became allies. But the path was not without its challenges. Similarly, as we usher in the era of robotics in textile manufacturing, we must navigate the intricacies of change while holding onto the values that define us. The future is not just about embracing technology; it's about understanding its place in the larger tapestry of human existence.

The narrative of textiles and technology is more than a story of machines. It's a reflection of our shared history, our aspirations, and the ethical quandaries that come with progress. As we continue to weave this tale, let us remember that it's not just about the threads and circuits but the hands and hearts behind them.

I know this firsthand because back in 2010, I founded a Smart Textile company that, from a kitchen table to operations in multiple countries, became the leader in the field.

A brief of what was the beginning of an incredible technological feat!

Drawing from the narratives of the past, the rise of robotics in textile manufacturing can be seen as a reflection of humanity's ceaseless quest for progress.

We, as a species, have always been driven by a need to improve, refine, to evolve. Yet, with every leap forward comes a myriad of ethical dilemmas. As we integrate machines into an industry steeped in tradition, one can't help but wonder: At what cost does this evolution come? The terrible stories about "sweatshops" in less developed countries are about to be reshaped as much as the profit-making machine agenda.

In a world where sustainability and technological innovation intersect, the textile industry stands on the brink of a significant transformation. Michael Fraede, the brain behind robotextile, together with experts like Michael Müller and Maike Rabe, is leading the charge in integrating modern robotics into textile manufacturing—a move poised to revolutionize the industry.

Industry Expertise

Michael Fraede, with his vast 34-year experience in robotics, has been a pivotal figure in bringing automation to consumer goods and textiles. Michael Müller, from erler GmbH, echoes Fraede’s sentiments, emphasizing the role of automation in reviving and maintaining regional production bases. Maike Rabe, a notable professor at Niederrhein University of Applied Sciences, points out the current lag in automation within the textile industry, highlighting the urgent need for innovation and modernization.

When building our own textile company, we experienced the full extent of that painful last statement. We had to create all sorts of tools and jigs to get from a working prototype to a manufacturable product. Tesla knows something about this type of manufacturing dilemma.

An example of from "prototype" to "manufacturing ready" can be demonstrated with the stages of what Victoria and I witnessed firsthand in the trenches. The photo below is a multimeter checking resistance based on foot pressure.

Months later (and many white nights later), we created a fully engineered system to validate the manufacturing quality and track defective hardware of socks combo by QR codes.

All that work resulted in global rewards in languages that we couldn't even understand the underlying alphabet of that language.

Addressing Challenges

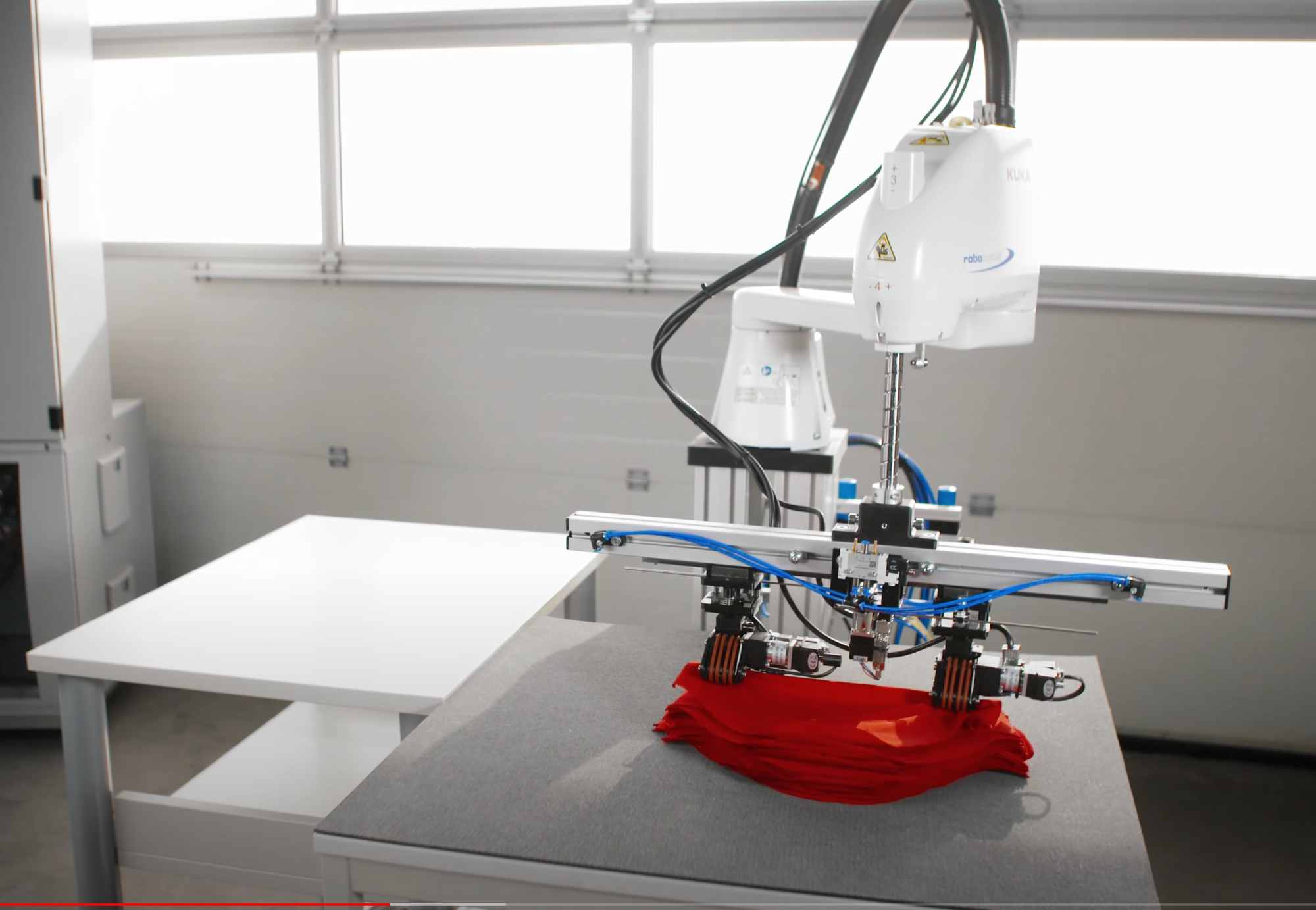

The textile industry faces unique challenges, especially in handling flexible parts like fabric. As revealed in a recent video, a significant portion of labor costs in large textile companies is attributed to simple tasks like fabric handling. Automating these secondary processes could pave the way for more economical production, especially in regions like Europe, where textile machinery has already seen significant automation.

Technological Solutions

The intricacies of separating fabric layers, given the industry’s diversity, call for specialized solutions. Technologies like flow grippers for heavier textiles, drum grippers for thin fabrics, and rubber parallel grippers for special textiles are being employed. Robots such as the KUKA AGILUS and SCARA series, known for their less than ten kilograms effective load capacity, are increasingly favored for their precision and versatility.

dubbed in English from the original (German)

Innovative Approaches

A groundbreaking development in the sector is the introduction of dual-layer control. By embedding sensors into fixtures, single layers of different fabric variants can be accurately managed. This innovation is not just a technological leap but also aligns with broader ethical and environmental goals, as evidenced by C&A's decision to resume "Made in Germany" jeans production under the new Supply Chain Act.

Ethical and Environmental Considerations

Jürgen Mohs from C&A’s FIT company highlights the critical role of robotics in ensuring supply chain stability and bringing back lost proprietary technology. The automation shift is changing daily operations, moving away from mundane tasks to more meaningful activities for operators.

The Future of Textile Manufacturing

The automation of textile manufacturing in Europe, driven by resilience, user-friendliness, and economic appeal, stands as a testament to the industry's commitment to sustainability. The move towards local production resonates with the global drive for environmental, ethical, and economic improvements. This revolution, spearheaded by visionaries like Fraede, Müller, and Rabe, marks a new era for the textile industry, where modern robotics blends seamlessly with traditional craftsmanship to create a sustainable, efficient, and ethically responsible manufacturing landscape.

There's more to come on this subject as the new generation of entrepreneurs replaces the original owners of those manufacturing facilities that, in many cases, even if of considerable size, are still running in a mom-and-pop style. When the generational transformation happens, you will see new robotics entering in en-mass, and AI will be at the top of that food chain!

Stich on bot, chop chop 😅