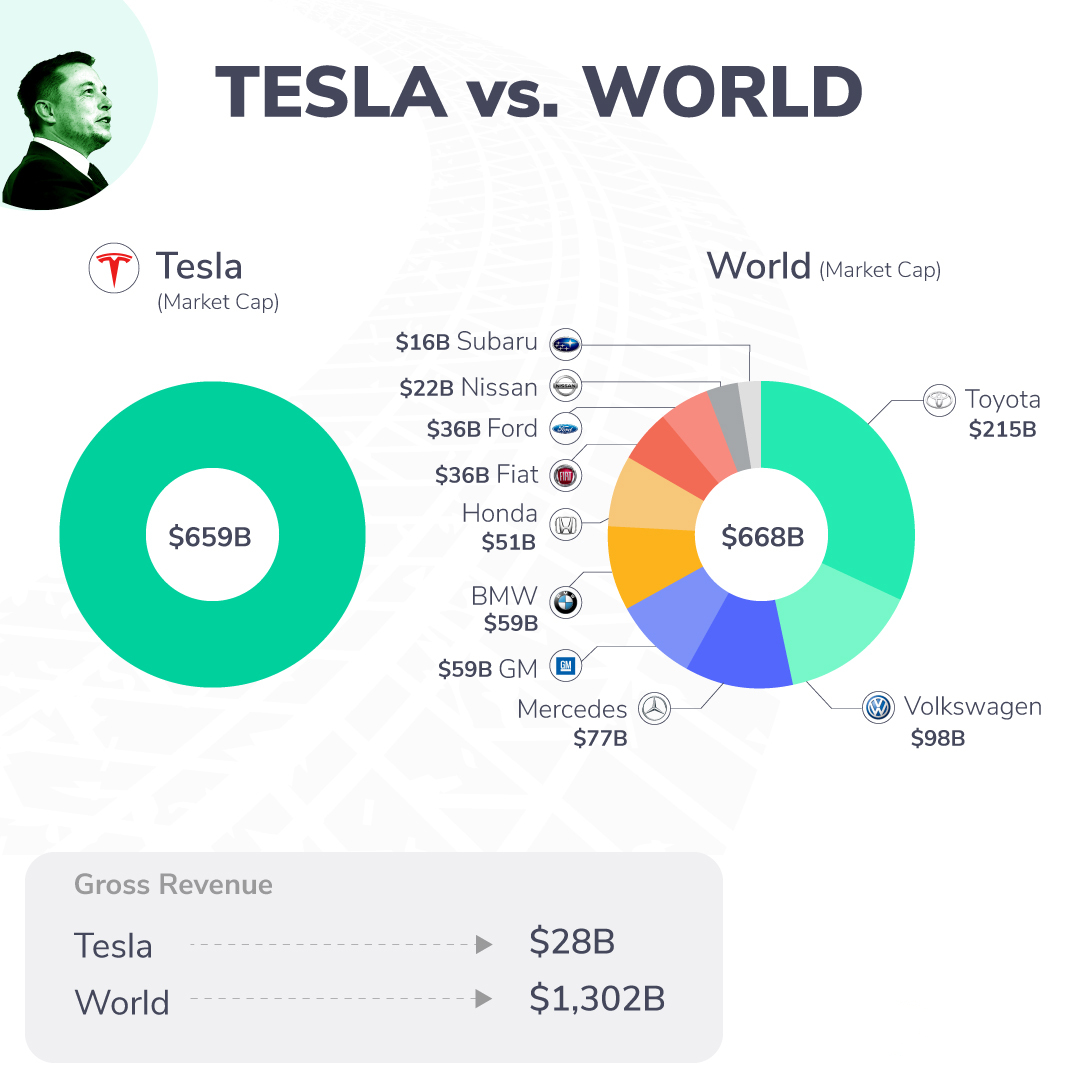

Less than a decade ago, you would not have even considered at any degree of seriousness to commit a large amount of money to an electric vehicle. As the tales tell, things have changed. And all it took was ONE element. A powertrain. Nowadays, you can't ignore the plethora of Tesla-branded cars on parking lots.

The same can be said for touchscreen phones; when the world was dominated by a plastic keyboard wrapped in some berry shell. It took one disrupting element to capsize the assumptions in both makers and consumers. The rest is history

We are on the cusp of witnessing an "iPhone moment" in the space of humanoid and robotics overall. And it appears by all accounts that the company in the lead for crossing that very high bar is Tesla. They have two elements of disruptions that no one else, at the time of this writing, has under one balance sheet and operational control. That is:

Custom actuators and neural nets capacity

Neural what?

Alright, here is the deal, think of neural nets like a mini-brain for Tesla's cars and robots. They help Tesla's machines learn from what they see and experience, just like how your brain helps you learn from playing games or riding a bike. In Tesla, neural nets help the car or robot understand what's going on around them, like knowing if there's a cat crossing the road, so they can make smart decisions, like stopping the car to keep the kitty safe.

We take pride in making reader digestible, topics that by their nature, are for the elite of their domain. And not oversimplifying so much (at least we try hard) that the technological complexity is obfuscated to a degree of nonsense. As per popular request via our Telegram channel, this is the first article of a series that aims to distill from the beginnings of Tesla Optimus to the latest information available, connecting the dots and when fact-checked, providing some real-world insights.

If the name Optimus isn't familiar in your robotics vernicular, let me bring you up to speed with one picture.

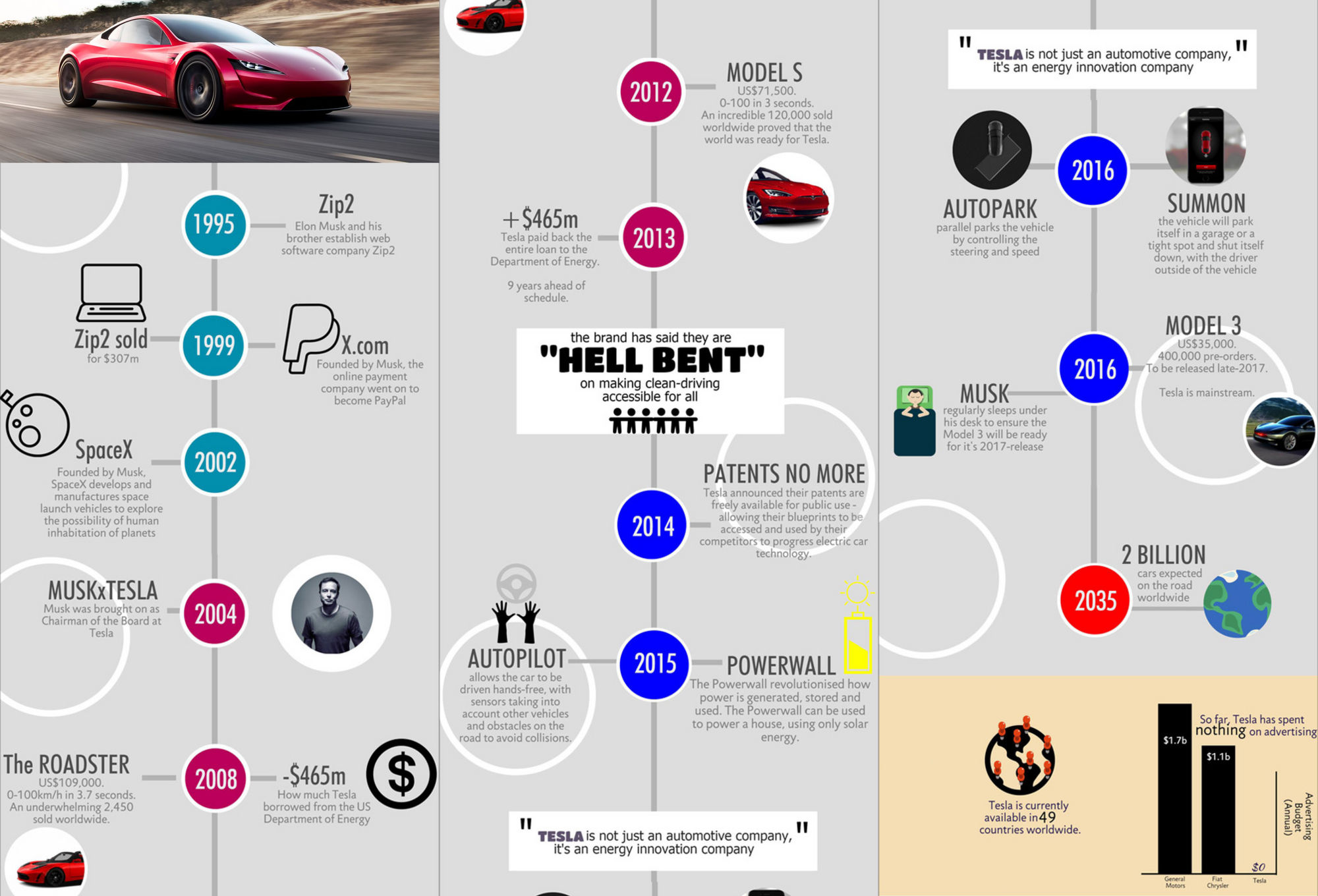

Tesla's Optimus, also known as Tesla Bot, is a humanoid robot project under development by Tesla, Inc. It was introduced during the company's Artificial Intelligence (AI) Day event on August 19, 2021, with Elon Musk, the CEO of Tesla, suggesting that a prototype would likely be built by 2022.

a quick recap of their very long shareholder meeting

The project has advanced to a stage where at least 13 working prototypes have been created at the time of this writing. The first batch was built using off-the-shelf parts. They have now entered the phase of "we know better what we are doing; therefore, we go custom and scalable."

Basic Specs

| Feature | Description |

|---|---|

| Type | General-purpose robotic humanoid |

| Height | 173 cm |

| Weight | 57 kg |

| Tasks Capabilities | Assembling car parts, moving components, picking up groceries |

| Movement Abilities | Walking, waving, gripping with fingers |

| Intended Use | Assisting in Tesla's car factories |

| Projected Availability | 2027 (within three to five years from the announcement in 2021) |

| Projected Price | $20,000 |

| Technology Base | Shared with Tesla's Full Self-Driving (FSD) autonomous software |

| Cross-Technology Application | Indication of crossover in AI technologies between Tesla's automotive and robotics endeavors |

It should noticed that Elon has a trend of creating enthusiasm around his projects, and way too many times, he is outrageously optimistic about target dates. However, to his credit, he might be optimistic like a kid in a candy store but absolutely reliable in terms of actually making it happen, at some point. The Tesla robotics division has been incredibly steady in making progress in a reasonably short period of time.

To put this in perspective, consider that just ONE year ago, their prototype could only move while on a pedestal, tethered and with commands sent from a backstage console. And the latest prototype is walking on his own and sorting objects like a human.

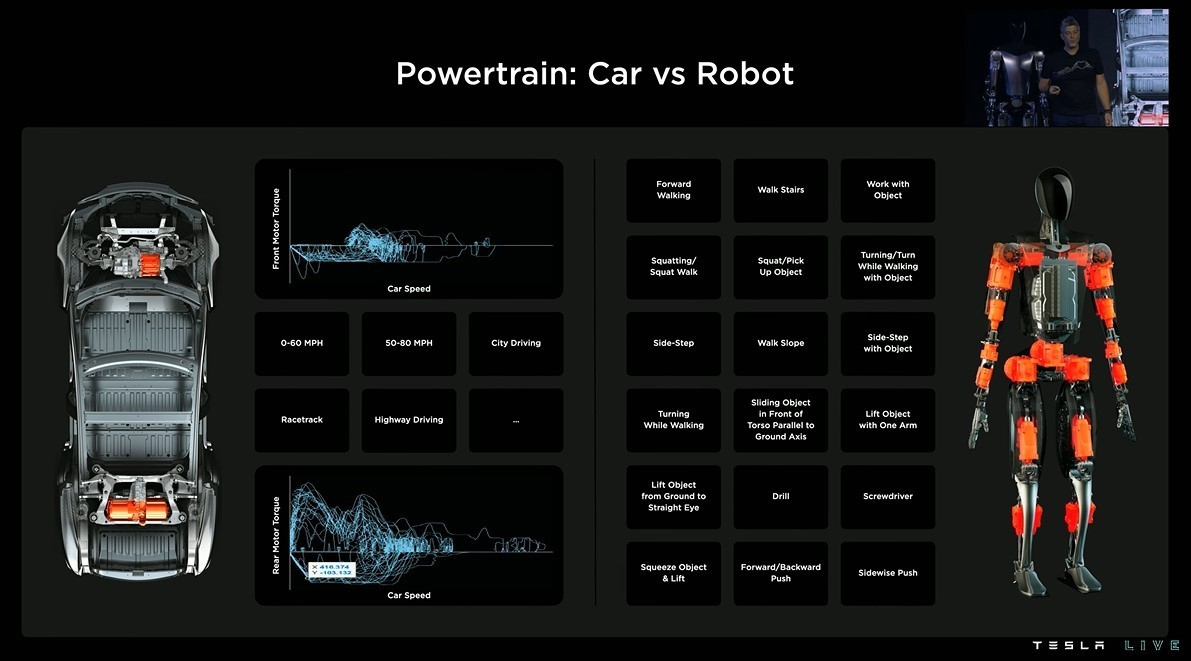

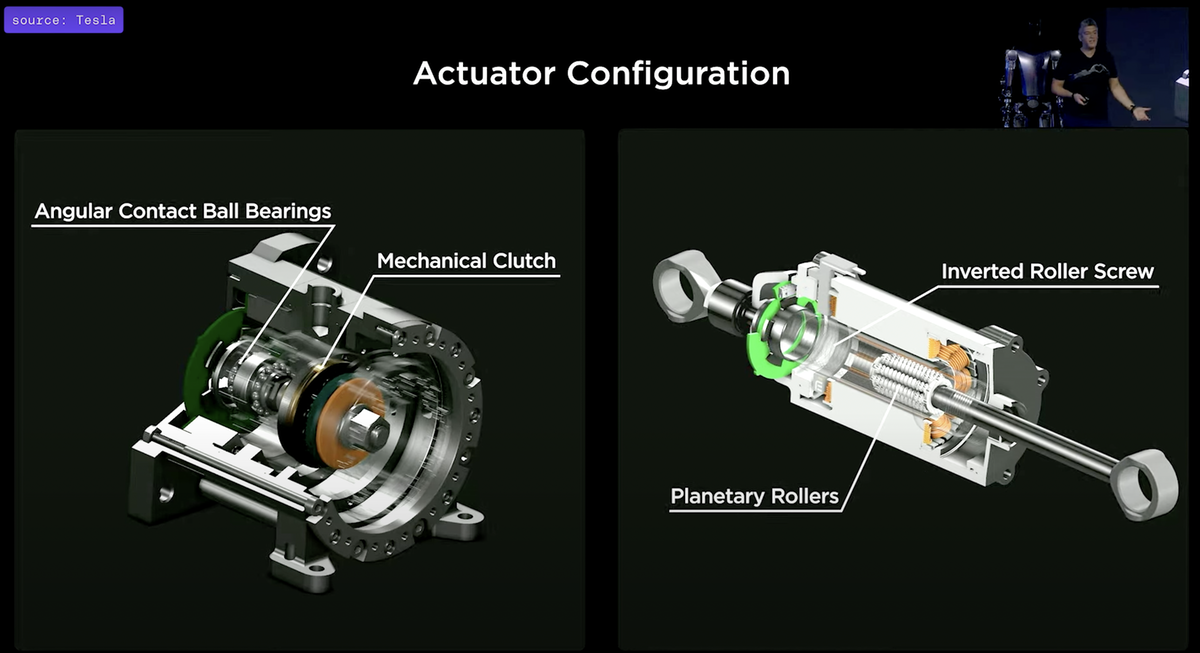

I made a crucial point at the beginning of the article: the iPhone moment for Tesla Robotics is composed of actuators and real-life AI. Let's tackle the first one on that list. The key part of a gas-moving vehicle is the drivetrain. The equivalent piece of a humanoid is an actuator. Tesla shifted from an almost-dead company to an absolute rocking power by inventing a powertrain that has nothing to envy the drivetrain. And the results speak for themselves.

Powertrain vs Drivetrain

The terms "drivetrain" and "powertrain" are often used interchangeably, but they refer to different components of a vehicle. Here's a breakdown of the differences between the two:

- Definition:

- Powertrain:

- The powertrain includes all the components that generate power and deliver it to the wheels of the vehicle. This encompasses the engine, transmission, the driveshaft, differentials, axles, and in some cases, the wheels.

- Drivetrain:

- The drivetrain includes all the components that are involved in propelling the vehicle but excludes the engine. This encompasses the transmission, driveshaft, differentials, and axles.

- Components:

- Powertrain:

- Engine (or motor in electric vehicles)

- Transmission

- Driveshaft

- Differentials

- Axles

- Wheels (in some definitions)

- Drivetrain:

- Transmission

- Driveshaft

- Differentials

- Axles

- Functionality:

- Powertrain:

- The powertrain is responsible for generating power (via the engine or motor) and delivering this power to the road surface to propel the vehicle.

- Drivetrain:

- The drivetrain is responsible for transferring the power generated by the engine to the wheels to propel the vehicle.

- Scope:

- Powertrain:

- The powertrain has a broader scope as it encompasses all the components from the engine to the wheels that are involved in generating and transmitting power.

- Drivetrain:

- The drivetrain has a narrower scope as it excludes the engine and focuses only on the components involved in transmitting the generated power to the wheels.

Japanese manufacturing principles have laid a foundation for numerous modern innovations. Their emphasis on efficiency, continuous improvement, and quality has spurred advancements in various fields. Their rise in North America has strong foundations on their making of the powertrain. Keeping high quality and lower manufacturing costs developed a cascade effect that made the king of the plaza for decades.

Tesla is in the process of applying all the knowledge that has developed from moving cars to moving bots!

The Tesla Bot is equipped with 23 actuators

And to really appreciate what that means, we need to go to actuator school for a moment without experiencing Windows Blue Screen of Death.

Actuators are devices that convert energy into motion.

Actuators can be powered by a variety of energy sources, including electricity, hydraulics, and pneumatics. Electric actuators are the most common type of actuator. They are relatively inexpensive and easy to control.

Hydraulic actuators are used in applications where high forces are required. They are also used in applications where the actuator needs to be able to operate in harsh environments. Hydraulic actuators are commonly used in construction and agricultural equipment.

Pneumatic actuators are used in applications where speed is important. They are also used in applications where the actuator needs to be able to operate in a clean environment. Pneumatic actuators are commonly used in medical and food processing equipment.

Actuators can be classified into two main types: rotary and linear.

| Aspect | Rotary Actuators | Linear Actuators |

|---|---|---|

| Motion Conversion | Convert electrical energy into rotational motion | Convert electrical energy into linear motion |

| Common Applications | Driving motors, fans, and pumps | Moving objects up and down, back and forth, or in and out |

| Functionality | Facilitate rotational movement in machines | Facilitate linear movement in machines |

| Importance | Essential for machines requiring rotational interaction with the environment | Essential for machines requiring linear interaction with the environment |

| Interactivity with Environment | Allow machines to interact with the environment through rotational movements | Allow machines to interact with the environment through linear movements |

To fully appreciate how quiet, powerful, and controllable their design is, you must take a look at the video below because if I try to spell it, my brain might explode with an adrenaline rush.

In the follow-up to this article, we will explore in further detail why their actuator design is absolutely insane! However, as a sneak peek, take a look at the demonstration below to appreciate what level of micro-movement the software can drive the hardware.

That's all I know so far. [Pink is right] see you in the episode of this new series dedicated to Tesla Robotics.

![From Tesla to BMW, humanoids are on their way [to your] home](/content/images/size/w300/2024/02/top_humanoids.png)