In a world where instant gratification is increasingly the norm, the idea of waiting weeks or even days for a product to be manufactured and shipped can seem almost archaic. Enter 3D printing, a technology that is poised to revolutionize the way we create and consume.

From rudimentary prototypes to intricate, custom designs, the capabilities of this technology have expanded at an astonishing rate. But it's not just the tech enthusiasts who are excited.

Manufacturers, engineers, and designers are all starting to realize the potential impact of 3D printing on the future of manufacturing. I believe we stand on the precipice of a new era in production—one where we can turn digital designs into physical objects at the click of a button.

This is not just about faster production times; it's about the ability to create objects that were previously unimaginable, whether due to complexity, cost, or both.

3D Printing in Rapid Prototyping

As someone who's witnessed and indulged in 3D printing firsthand, I can't overstate its impact on the realm of prototyping. Traditionally, creating a prototype was a lengthy and expensive process.

It involved designing a model, creating a mold, which could be made with clay or wood and then casting the prototype. Often, this process had to be repeated multiple times until the final design was perfect. With 3D printing, however, the game has changed entirely.

3D printing has firmly established itself as an essential tool for rapid prototyping. This technology allows designers to create a physical model of a design directly from a CAD file. It has streamlined the process of prototyping, turning it from a cumbersome and time-consuming ordeal into a quick and easy task.

Moreover, 3D printing allows for greater flexibility in the design process. Traditional prototyping methods can be limiting, especially when it comes to complex or intricate designs. With 3D printing, these restrictions are all but gone. You can create virtually any design you can imagine, no matter how complicated or detailed.

One standout example of 3D printing being utilized for rapid prototyping is in the automotive industry. Companies like Ford and BMW have been using 3D printers to create parts for test vehicles. Instead of waiting for parts to be manufactured and shipped, they can create them in-house in a fraction of the time.

Another noteworthy example comes from the medical sector. Biotech firms are utilizing 3D printing to create anatomically accurate models of human organs. These models are invaluable for surgical planning and education.

By shortening the feedback loop between design and testing, 3D printing facilitates rapid iteration, enabling designs to be perfected more quickly and efficiently. And as 3D printers become more sophisticated and affordable, their role in rapid prototyping will only become more critical.

Reshaping the Manufacturing Industry

Today, manufacturing is often a lengthy, resource-intensive process. Goods are produced in large quantities, often in distant factories, and then shipped worldwide. This system has many flaws, including high carbon emissions, waste, and long lead times.

But what if we could produce what we needed, when we needed it, right where we are? That's the promise of 3D printing.

Imagine a future where instead of ordering a product online and waiting for it to be shipped to your door, you simply download a design file and print it at home. It's a concept that's not too far off, with advancements in consumer-grade 3D printers.

3D printing could herald a new era of localized manufacturing, reducing the need for global shipping and its associated environmental impact. This kind of shift could have a profound effect on our economy, our environment, and our society as a whole.

And it's not just about localization. 3D printing also has the potential to democratize the manufacturing process. With this technology, individuals and small businesses can create products that were once only possible for large corporations.

In a quote that rings true in this context, Jeff Goldblum's character in Jurassic Park famously said,

"Life finds a way".

The same can be said for innovation and creativity. When barriers to entry are lowered, as they are with 3D printing, creativity finds a way.

Moreover, 3D printing opens the door to more sustainable manufacturing methods. By using only the material needed to create a product, waste can be significantly reduced. Plus, as development continues, we can expect to see more eco-friendly printing materials.

Looking ahead, 3D printing technology has the potential to fundamentally reshape the manufacturing industry—and that's just the tip of the iceberg. The broader societal implications of this technology are vast and exciting.

Fun and Interesting Facts About 3D Printing

Over the years, I've come across some fascinating tidbits about 3D printing. Here are a few that I find particularly interesting:

First 3D Printer: The first 3D printer was invented by Chuck Hull in 1983. He called the process 'stereolithography', and it laid the groundwork for the vast array of 3D printing technologies we see today.

3D Printing in Space: In 2014, the first 3D printer was sent to the International Space Station. Astronauts used it to print a wrench from a design file sent from Earth. It was a milestone moment for demonstrating the potential of 3D printing in space exploration.

World's Largest 3D Printed Structure: In 2019, the world's largest 3D printed building was constructed in Dubai, standing at two stories tall and spanning 640 square meters. It's an impressive testament to the capabilities of this technology.

3D Printed Food: Believe it or not, 3D printed food is a thing. From intricate sugar sculptures to plant-based meat substitutes, the culinary world is experimenting with what 3D printing can bring to the table.

3D Printing and the Film Industry: Hollywood has been quick to adopt 3D printing, using it to create props, costumes, and set pieces. One of the best-known examples is the mask worn by the villain in Black Panther, which was 3D printed!

3D Printing and Bio-printing: Perhaps one of the most fascinating areas of 3D printing is in bio-printing, where scientists are exploring the printing of human tissue and organs. While still in early stages, the potential implications for medical science are enormous.

Impact of 3D Printing on Various Industries

3D printing is not just revolutionizing the manufacturing sector—it's creating waves across numerous industries. From medical to automotive, fashion to construction, this technology is proving to be a game-changer. Let's explore how.

3D Printing in the Medical Field

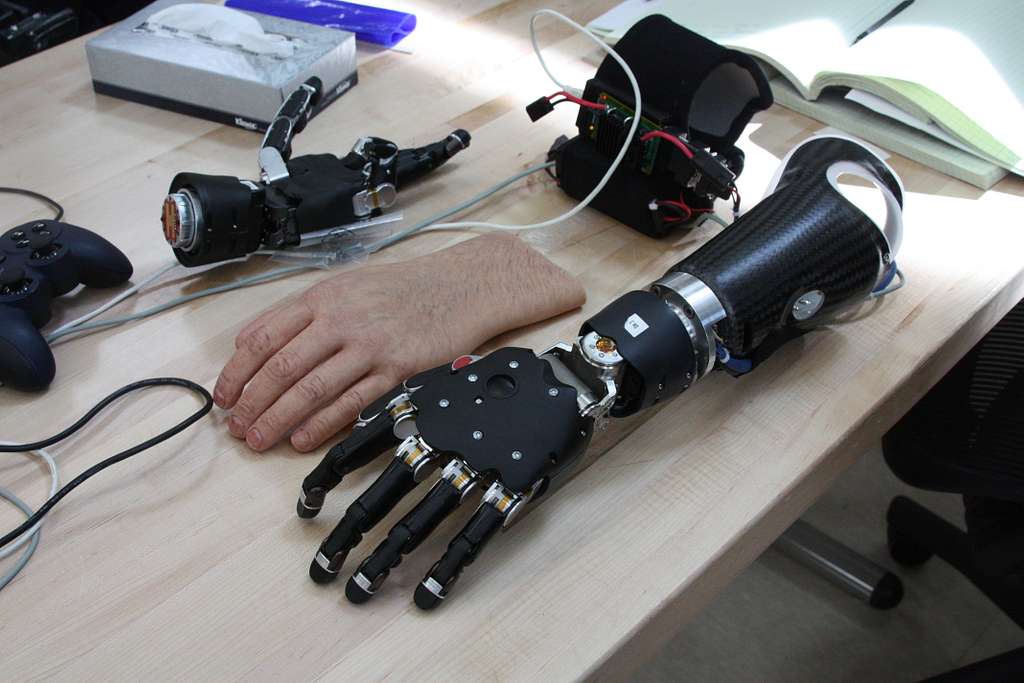

Few things have fascinated me as much as the use of 3D printing in the medical field. This technology is driving groundbreaking advancements, particularly in the creation of prosthetics, medical devices, and even human tissue.

By creating customized prosthetics and implants, 3D printing is helping to improve patients' quality of life. For instance, it's now possible to 3D print a prosthetic limb tailored to an individual's specific needs and measurements. This personalization enhances comfort and functionality, making a significant difference in the lives of amputees.

3D Printing in the Automotive and Aerospace Industries

3D printing has also found a place in the automotive and aerospace industries. Companies in these sectors are leveraging this technology to produce parts more quickly and cost-effectively. From prototyping to the production of end-use parts, 3D printing is changing the game.

In the automotive industry, companies like BMW are using 3D printing to create parts for their vehicles, reducing both costs and production times. In aerospace, giants like NASA are exploring the use of 3D printing for manufacturing components of spacecraft. The potential for creating lightweight, strong, and complex parts makes 3D printing an invaluable tool in these industries.

3D Printing in the Fashion Industry

When you think of fashion, 3D printing may not be the first thing that comes to mind. But let me assure you, it's making its mark here too. Designers are using 3D printers to create everything from jewelry and accessories to footwear and garments. This technology allows for a level of customization and complexity in design that was previously unthinkable. And with the advent of sustainable 3D printing materials, this could also become an eco-friendly alternative in an industry known for its environmental impact.

3D Printing in the Construction Industry

The potential of 3D printing doesn't stop there. In the construction industry, companies are experimenting with 3D printed buildings. While this may sound like science fiction, I can assure you it's very much a reality. These machines can construct houses and other structures much faster than traditional methods, and at a lower cost. Moreover, they offer the potential for creating buildings with more complex designs and less waste.

In the words of Arthur C. Clarke,

"Any sufficiently advanced technology is indistinguishable from magic,"

and I've got to tell you, as someone who's been reporting on this for years, 3D printing sometimes feels like magic.

From a concept in the mind of an inventor in the early '80s to the revolutionary force it's become today, 3D printing has indeed come a long way. We've explored its potential in rapid prototyping, its impact across various industries, and the exciting possibilities for its future.

We've seen how it could reshape the manufacturing industry, making it more localized, democratic, and sustainable. We've marveled at its ability to print everything from wrenches in space to a two-story building, from intricately designed food to film props and costumes.

However, as much as we have covered, there's always more to the story. This technology is evolving at a breakneck speed, and its potential uses are only limited by our imaginations.